Our products

Discover our range of specialized products designed to meet the demanding needs of the aviation, oil & gas, and industrial sectors. From advanced filtration systems to refueling equipment and self-contained storage tanks, we provide reliable and efficient solutions.

Faudi Aviation

FAUDI Aviation GmbH is a family-owned, medium-sized company specialized in the filtration of civil and military aviation fuels. Our product portfolio consists of over 850 products distributed in more than 80 countries worldwide. Founded in 1938, FAUDI Aviation is today the leading premium brand that stands for quality, innovation and safety. Behind the brand, teams of both young and experienced employees work on the technological challenges of tomorrow.

Filter Vessels

Stationary or mobile, these are high quality “filtration systems” for the management of contaminants in jet fuels. Filter Water Separators to filter solids and remove water, clay filters for surfactants, dyes and additives, basket strainers for coarse pre-filtration, microfilters and Dirt Defense filters for continuous filtration of solids (particles, sediments, dusts…). FAUDI products are designed according to the standards and standards applicable in commercial, military and general aviation.

Filter Elements

The filter elements meet aviation standards. Coalescers and separators are used in Filter Water Separators as first and second stage of free water removal. Upstream, microfilters protect the life of the coalescer elements by effectively removing the finest solid particles.

Sensor Technology

A range of electronic sensors for continuous monitoring of fuel quality and ensuring the performance of filtration processes. Afguard electronic water sensors for on-line water content measurement and Slugguard for low point checks. Dpguard system and touch screen controller for measuring differential pressure during refuelling and fuel contamination levels. DP switches and DP Transmitter to manage fuel differential pressure and flow during refuelling.

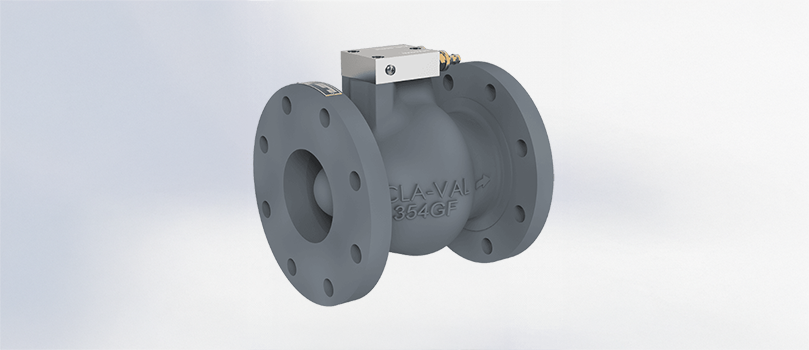

CLA-VAL

Since 1936, Cla-Val has been known as the leading manufacturer of automatic control valves and has built a well-earned reputation for providing superior quality products designed for mission-critical water distribution solutions throughout the United States and around the world.

We accomplish this through a unique combination of engineering expertise, craftsmanship, quality materials, sophisticated manufacturing processes and superior customer service, backed by the best warranty in the business

We accomplish this through a unique combination of engineering expertise, craftsmanship, quality materials, sophisticated manufacturing processes and superior customer service, backed by the best warranty in the business

Ground Fuelling and Hydrant Systems Material & Services

We offer the wholerange of products an airport may need to supply fuel to aircrafts. We assist in selecting and providing equipment, in training and maintenance, in handling mandatory checks and controls, in helping in the design and management of your installation.

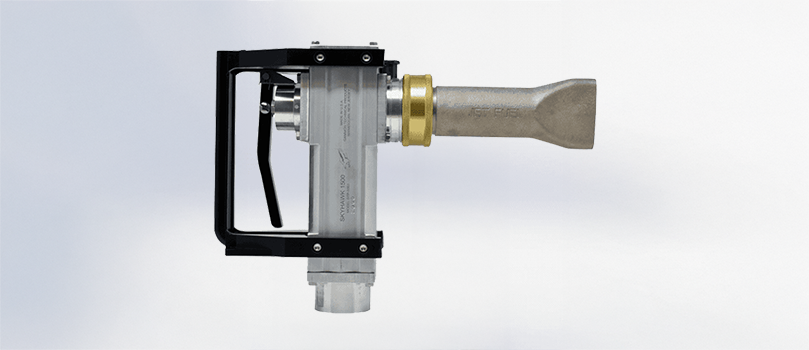

Underwing Nozzles

Commercial aviation and military aviation standards compliant equipment for refuelling under pressure.

Hydrant Couplers

Pressure control equipment and systems for fuel distribution with specific connection. Designed according to the EI-1584 standard and ensuring durability and ease of maintenance.

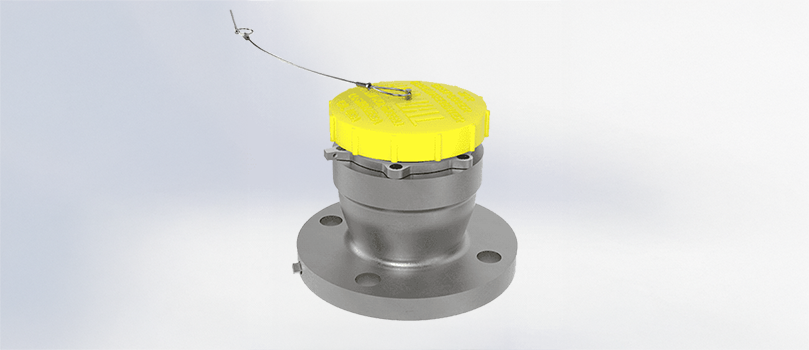

Hydrant Valves

Dual pilot manual/pneumatic equipment. Designed according to EI-1584 standard enabling reduced operating costs.

Pressure Control Valves

A wide range of fuel flow control valves.

Overwing Nozzles

Refuelling Nozzles for general aviation and helicopters.

Equipment for Hydrant Systems

A complete range of complementary equipment: hydrant pit boxes, hydrant pit lids, high-low point arrangement, hydrant isolating valves, valve chambers.

Silea Liquid Transfer

Silea was born in 1968, sensing the future development of the oil sector, both in the distribution and in the transfer of products.

Located in the district of Bologna, in Ozzano dell’Emilia, over the years, the company specialized in the transfer of hydrocarbons, producing loading and unloading arms, floating suctions, pumps, folding stairs for tank trucks, etc.

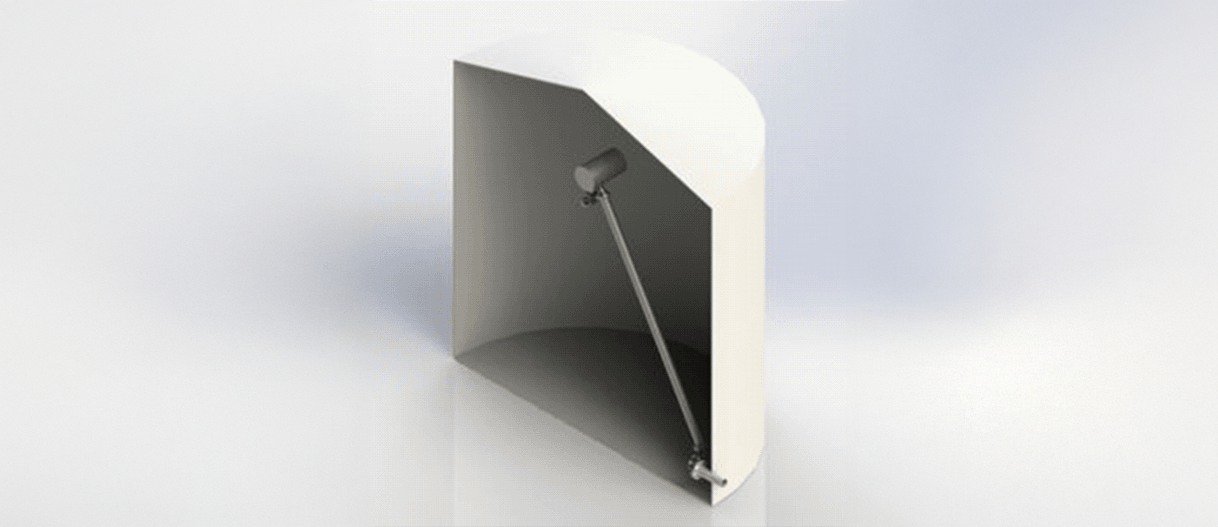

Floating Suction for Tanks

The floating suctions are used in tanks, above ground or underground, and allow the suction of the clean product near the surface, without the sediments that are normally found on the bottom of the tanks.

Top Loading Arm

The top loading arm is an articulated piping supported by a mechanical balancing (torsion or compression spring) or pneumatic system, which is used to transfer fuels or industrial liquids in tankers and railway tanks through the top manholes.

Bottom Loading & Unloading Arms

The bottom loading arms are used to load/unload tank trucks and railway tankers for fuels and industrial liquids. This transfer system offers the advantage of operating directly on the ground instead of getting on the tank and thus avoids the formation of electrostatic charges generated.

Folding Stairs for Trucks

The Silea Liquid Transfer 3700 serie Folding Stair is designed to allow access from the platform to the manholes of tank trucks and rail-wagons. The stairs automatically adjust to the height of the tank and can be designed with 3, 4 or 5 steps, with or without safety cage.

Metering Skid

Silea metering skids are compact solutions, designed to meet all loading, unloading and additivation needs, in places with logistical difficulties or with temporary needs, for example construction sites. Depending on the requests, skids can be equipped with all the accessories that normally compose a loading station, but with small and functional dimensions for moving. They can be designed with one or more loading arms, bottom or top, as needed, with variable flow rates from 500 to 2000 l/min.

Avery-Hardoll Fuel Meters by Silea

Avery-Hardoll flowmeters are precision made, positive displacement, liquid measuring instruments manufactured by Silea Liquid Transfer. In 2021, Silea acquired the Avery-Hardoll product line. Since 1932, simplicity of design and construction together with sustained accuracy has led to the widespread use of Avery-Hardoll meter products including the BM Series meters and MASTERLOAD.iQ™ electronic registers by Liquid Controls, on aviation refuelling vehicles throughout the world.

Leader in Measurement Accuracy

With proven measurement accuracy as good as 0.05%, Avery-Hardoll meters remain unmatched in maintaining the most accurate fluid measurement in the world. The proprietary Avery-Hardoll meter design remains the industry benchmark that many have struggled to emulate, because “It’s what’s on the inside that counts”.

The first flowmeters built for aviation fuel. An ideal product to be installed on metering skids, for all oil & gas applications.

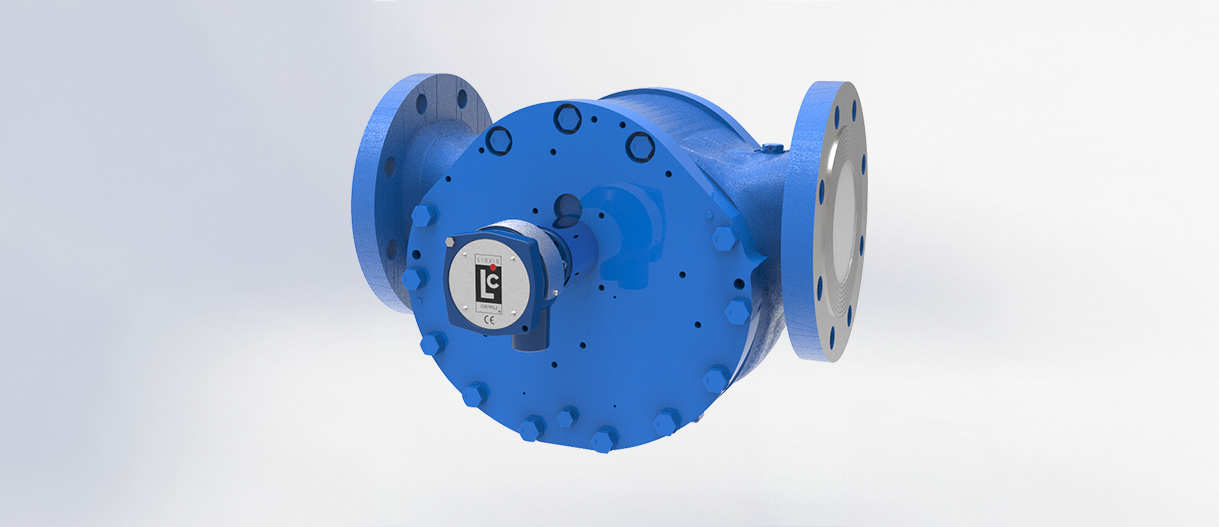

BM Series Flowmeters

The BM Series flowmeter directly converts volume to rotational output with minimum scope for error and with minimal disturbance from surrounding conditions, such as turbulence from nearby valves, bends, and other system conditions.

DM Series Flowmeters

The Avery-Hardoll Steel DM Series flowmeters are precision made, positive displacement, liquid measuring instruments that maintain the highest level of accuracy over a lifetime of operation. The DM meter is specifically designed to meet the rigorous demands of modern tank truck loading depots and fuel storage facilities as well as other niche applications.

MASTERLOAD.iQ™ Electronic Register

The MASTERLOAD.iQ™ allows OEMs and end-users to fully customize the fueling experience with configurable screens and tickets, adaptable software, real-time on-screen diagnostics, and remote data access with control. This product paves the way for virtually infinite expandability, making it ideal for applications requiring flexibility and enhanced safety.